If you buy through affiliate links, we may earn commissions, which help support our product reviews.

Last Updated Feb 6, 2024

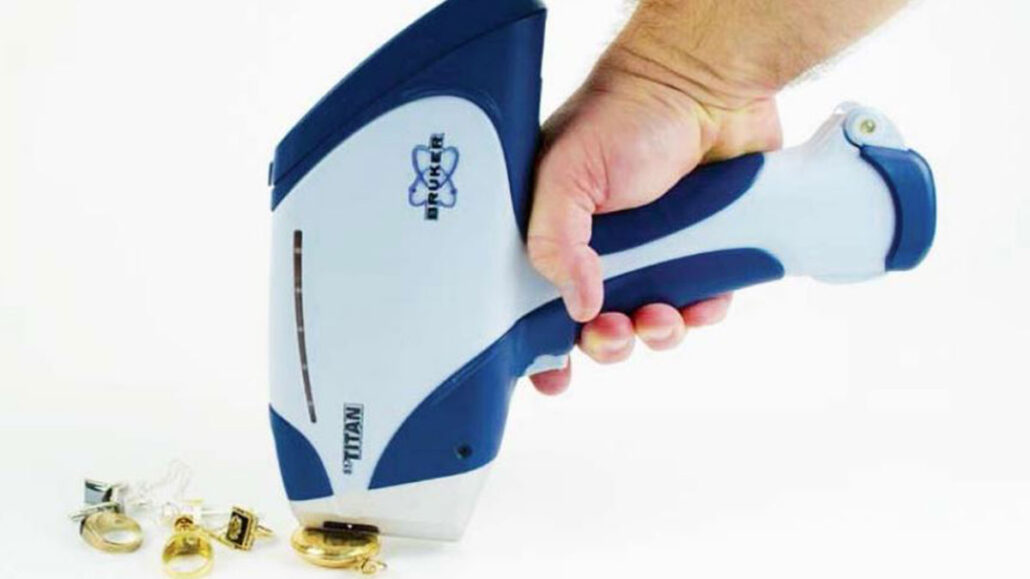

As industries remain steadfast in their pursuit of precision and efficiency in metal analysis, this Bruker X-ray Fluorescence Analyzer (XRF) has emerged as a formidable contender.

This portable device is designed explicitly for metallurgists, scrap metal sorters, and precious metal analysts. It goes beyond being just a lab on the go – it serves as the foundation for efficient operations where accuracy is paramount.

In our comprehensive Bruker S1 Titan 800 Review, we delve into the nitty-gritty of its performance and user experience, solidifying its status as an industry benchmark.

Also, don’t forget to check out our post on the best handheld XRF analyzers to compare the top 3 XRF guns currently on the market in 2024.

Real-World Testing and Results

In our extensive field tests, the Bruker S1 Titan 800 demonstrated unparalleled material identification proficiency, boasting a precise detection capability down to parts per million. This level of accuracy is crucial for industries where material composition dictates value and application, such as jewelry or aerospace manufacturing.

As tech enthusiasts at Trakkit, LLC, we scrutinize the equipment’s reliability under actual industrial conditions—think noisy scrapyards and dusty mine sites—and the S1 Titan 800 consistently delivers results with an ease of use that redefines efficiency in material analysis.

Bruker S1 Titan 800 Review

Technology: Alloy-grade identification technology

Engine: High-speed processing engine

Design: Ergonomic, lightweight design

Protection: IP54-rated environmental protection

Camera: Integrated camera for precise targeting

Reporting: Advanced reporting with a touchscreen

Pros

- Exceptional resolution and speed

- Analyzes Mg to U spectrum

- Durable, IP54 rated design

- Portable and lightweight

- Versatile calibration options

- Wi-Fi and USB connectivity

Cons

- High initial cost

- Learning curve for beginners

Specifications

| Specifications | Details |

|---|---|

| Measurement Technology: | X-Ray Fluorescence (XRF) |

| Detector: | Silicon Drift Detector (SDD) |

| Elemental Range: | Titanium (Ti) to Uranium (U) |

| Alloy Calibration Range: | Fe, Al, Cu, Ni, Co, Mg, Ti, and more |

| Data Storage: | Extensive memory with MicroSD & USB support |

| Battery Life: | Up to 8 hours of continuous use |

| Operating Temperature: | 14°F to 122°F |

| Display: | Fixed angle, color, touch-screen |

| Dimensions: | 9.9″ x 3.1″ x 12″ |

| Weight: | 3.3 lbs |

| IP Rating: | IP54 (protection against dust and water) |

| Calibration: | Automatic with Bruker’s patented Calibration |

| Reporting: | Customizable reports for different requirements |

High-Impact Features of the S1 Titan 800

The flexibility it lends to professionals is remarkable for a portable device weighing merely 3.3 lbs.

Its 20mm2 Graphene window SDD detector sets a new standard for resolution and capability, achieving a resolution of less than 145eV @450,000cps, a feat that significantly outperforms its competitors.

The device doesn’t just excel in single-line performance. It triumphs in its ability to analyze the spectrum from Magnesium to Uranium (Mg to U). Due to its versatility, this tool can be applied in various applications, making it a valuable asset.

Moreover, the wide range of calibration options ensures that the device is primed for accurate readings, whether mining explorations or consumer product safety tests.

The portability is underscored by its resistance to field conditions, thanks to the IP54 rating that shields it from dust and humidity.

With the option for desktop and benchtop stands, this analyzer is adaptable to various sample sizes and shapes for measurement, ensuring universal usage.

The Nexus of Precision and Adaptability

The Bruker S1 Titan 800 is not just about raw performance. The presence of nuanced features like the SMART Grade timing for rapid alloy identification and the inclusion of Wi-Fi and USB connectivity streamlines data usage in a digital age.

The patented TITAN Detector Shield (TM) is a testament to the device’s focus on user needs, providing a robust exterior for the delicate detection technology.

The S1 Titan 800 from Bruker stands out with its capacity to analyze light elements such as magnesium, aluminum, and silicon swiftly without requiring a vacuum or helium atmosphere—a significant advantage for a device of its class. This not only saves time but also empowers users to make prompt decisions based on precise data.

Whether it’s optimizing the value stream of raw materials or ensuring product safety, this capability enhances efficiency and effectiveness.

In the Hands of the Practitioners

While the Bruker S1 Titan 800 is laden with pros, a critical glance highlights a few cons. The initial investment may be a barrier for smaller businesses, albeit one that can be mitigated by its broad applicability that could replace multiple devices.

Calibration setup, while allowing for a high degree of customization, may present a learning curve for novices.

Nevertheless, with a plethora of online resources and strong customer service backing, mastering this device is an investment in the future of metal analysis.

Comparatively, the S1 800 holds its own against the current market offerings. While it may not claim the featherlight weight of some competitors, its robust performance and adaptability make it a compelling choice for serious professionals seeking a future-proof material analysis solution.

Bruker S1 Titan 800 Price

Potential buyers should know the pricing structure of the Bruker S1 Titan 800 XRF Analyzer before investing.

The starting price for this advanced piece of equipment is around $27,000. This initial cost includes the analyzer and basic calibration settings to get you started. For those considering the acquisition of multiple units, a scaled pricing model is available, potentially reducing the cost per unit. We encourage interested parties to contact us directly for a tailored quote on multiple XRF analyzers.

Over time, calibrations are necessary to maintain the high level of accuracy and performance that the Bruker S1 Titan 800 is known for. Each calibration service is estimated to cost about $2,500. Please note that the calibrations should be performed by qualified technicians from the manufacturer. This ensures the maintenance of the highest standards of accuracy and reliability. Utilizing skilled technicians for calibration is crucial for the device to continue providing precise and reliable measurements across various materials and applications.

Investing in the Bruker S1 Titan 800 XRF Analyzer means acquiring a top-tier analytical tool and planning for its maintenance to ensure its longevity and effectiveness in your operations.

Bruker S1 Titan 800 vs. Niton XL2 Comparison

The Bruker S1 Titan 800 and the Thermo Scientific Niton XL3t are advanced handheld XRF analyzers with unique features and capabilities. Here’s a comparison based on the information gathered:

Bruker S1 Titan 800 | Thermo Scientific Niton XL3t |

|

|---|---|---|

| Detector: | High-performance graphene window silicon drift detector (SDD) | High-performance semiconductor |

| Weight: | Under 3.3 lbs with battery | Less than 3 lbs |

| Camera: | Integrated camera (640 x 480 pixels) for sample visualization | Integrated CCD camera |

| Display: | 640 x 480 pixels, 64k color, resistive touchscreen | Adjustable angle, color, touch-screen display |

| Software: | Bruker’s Instrument Toolbox for control and data manipulation | Niton Data Transfer (NDT) PC software suite for customization and data management |

| Connectivity: | Wi-Fi, and USB | USB, Bluetooth, and RS-232 serial communication |

| Calibration: | Metals Alloy PMI, Alloys with Light Elements, Limestone, Heavy Metals and Nutrients in Soil, Food Safety & Environment, Restricted Materials | Metal Alloy, Electronics Alloy, Precious Metals, Bulk Modes (Mining, Soil), Plastic Modes (RoHS Plastics, Toy & Consumer Goods Plastics), and other specific modes |

| Additional Features: | TITAN Detector Shield for protection, optional accessories, and a 2-year standard warranty extendable to 5 years | Integrated sample imaging system, 3 mm small spot feature, optional heat shield for hot-surface testing, and various accessories for sample testing |

Key Differences

- Detector Technology: Bruker uses a graphene window SDD, while Niton XL3t employs a semiconductor detector.

- Software and Connectivity: Both offer robust software solutions with different interfaces and features.

- Calibration and Applications: Each has specific calibration packages tailored to different applications.

- Design and Ergonomics: While both are designed for portability and ease of use, they have different weight and display features.

The choice between the S1 Bruker Titan 800 and Thermo Scientific Niton XL3t depends on specific application requirements, such as the materials being analyzed, the desired portability and ergonomics, and the need for specific software features and connectivity options. Both are high-performance tools worth considering, but the Titan S1 800 is the clear winner.

Final Verdict: Is the Bruker S1 Titan 800 Worth Investing in?

In the fast-paced world of metal analysis, where precision can mean the difference between profit and loss, the Bruker S1 Titan 800 XRF Analyzer shines as a beacon of accuracy, adaptability, and portability.

It’s a formidable ally for professionals ready to elevate their game, providing data and actionable insights quickly.

This handheld XRF analyzer may very well be the answer for operations where ‘optimum’ is the only option.

With its innate ability to inspire confidence and its knack for unraveling the complexities of material composition swiftly and effectively, the Bruker S1 Titan 800 XRF Analyzer remains a standard-bearer in the industry and is a worthy investment. If you need fewer performance features, look at our Bruker S1 Titan 500s review for a cheaper option.

Frequently Asked Questions about the Bruker S1 Titan 800

What is the typical price of a Bruker Handheld XRF analyzer?

The typical price of a Bruker Handheld XRF analyzer ranges from $6,000 to $30,000, varying based on the application, calibration, and hardware. It is always best to request a quote from the seller.

How does XRF work?

X-ray fluorescence (XRF) is a remarkably potent analytical technique enabling non-destructive analysis of the elemental composition across a diverse array of materials. With its precision and accuracy, XRF offers valuable insights into the chemical makeup of diverse samples without causing any damage. XRF analyzers direct X-rays at the sample, which then eject secondary (fluorescent) X-rays characteristic of the elements present. The composition of elements in the sample can be determined by analyzing the intensity and energy of fluorescent X-rays. This technique allows for precise measurements of type and quantity, providing valuable insights into the sample’s properties.

How accurate is the XRF test?

The accuracy of XRF testing is generally high, particularly for common metals in alloys. Compared to traditional assay methods, the method can achieve accuracy levels ranging from 0.2 to 0.5% for elements like gold. Enhancing precision entails augmenting the number of X-ray counts during testing. Numerous studies have established the reliability of XRF as a technique for screening diverse metal elements in various sample types.