If you buy through affiliate links, we may earn commissions, which help support our product reviews.

Last Updated: Apr 29, 2024

Today, there are not just tracking solutions for trucks, but trailers too. Advancements in telematics technology have allowed the transportation companies to install the same tracking technology as they use in vehicles.

Since refrigerated (reefer) trailers are an integral part of the supply chain, it’s a good idea to keep an eye on them.

Smart transportation agencies understand the value of reliable cold chain monitoring, and protecting the health of the public by maintaining their cargo at regulated temperatures.

In order to verify the optimal temperature in refrigerated trailers, they are switching to a subscription-free wireless reefer trailer temperature monitoring system.

In this article, we will explore many aspects of Refrigerated Trailer and GPS Temperature Monitoring Systems;

And introduce you to an excellent combined Reefer Temperature Monitoring and GPS Tracking System.

What is a Reefer Trailer?

A Reefer Trailer, also known as a Refrigerated Trailer, is equipped with a refrigeration unit, and insulation to help maintain temperature for perishable items like poultry, ice-cream, flowers, or even pharmaceuticals during transportation.

Reefer trailers are usually 53-feet long and have insulated roofs, doors, floors, and walls and have a refrigerator mounted on the front. They are also available in different sizes. This makes them an excellent solution to the long and short term storage for transportation.

Refrigerated Trucking companies, and Cold Storage Transportation, that specialize in moving perishable goods, use these trailers.

Additional Applications of Refrigerated Trailers include:

- Food Storage and Delivery operations

- Emergency response and disaster planning

- Medical and Pharmaceutical

- Military

History of Reefer Trailers and Trucks

Believe it or not, reefer trucks have been around with us for a long time. Before the 20th century and the invention of motor vehicles, temperature-controlled products were transported in limited quantities and for short distances only – using big chunks of ice.

Well, it has come a long way since then. In the 1920s, agencies in the USA used vehicles with cooled containers for the transportation of fish and meat for short distances.

In the year 1930s, commercial vehicles with mechanical cooling units built-in started to hit the roads. By 1939, Fred Jones invented the first portable air cooling unit.

How do Reefer Trailers Work?

A reefer trailer looks the same as a regular trailer, but they have insulation on the front and sides of the trailer. Insulated walls are made using plastic, steel, or non-porous material.

It may also have a translucent roof layer that is tear-resistant. The roof of the reefer trailer has the potential to reflect heat and UV waves, thereby maintaining a constant temperature.

Modern refrigerated trailers are equipped with alarms that alert the driver of the failures or set point issues, but you’ll be surprised how often the set points and alarms are missed by the driver and the load is spoiled.

Today, you will even find trailers equipped with tracking systems that track time and temperature automatically for auditing purposes.

Primary components of Reefer Trailers include:

a) Compressor

A small engine within a reefer unit drives the compressor unit. It draws in refrigeration and compresses it. The pressure inside condenses gas and liquid refrigerant and releases heat to the compressor body.

b) Condenser

The Condenser receives liquid from the compressor. At this point, heat gets exchanged within the condenser.

The heat from the liquid moves to the tubing walls and then outside to the attached fins. The fins offer more surface area to cool outside air drawn via condenser fan.

c) Evaporator

The evaporator is located inside the reefer trailer. The refrigerant that has released most of the heat to the condenser has turned it into a cool liquid. It is then released heat into the evaporator via a metering valve to control cooling.

In the evaporator, the refrigerant expands and becomes a gas. As it goes through the process, it absorbs plenty of heat from the surrounding finned coils. It removes heat by moving air over the fins circulating the refrigerant.

The trailer is cooled by releasing heat to the evaporator. The whole process continues to repeat until the desired temperature reaches.

Important Details about Reefer Trailer Temperature Ranges

When transporting perishable cargo you must set the proper Cooling Profile on your reefer unit so you don’t flash freeze the cargo as the cooling process starts.

As per Refrigerated Trailer Market Report published by Allied Market Research tells us that the international refrigerated trailer market has a $5.588 billion value in the year 2015. It is also expected to grow $7.658 billion by the year 2022.

Trucking and transportation companies need to ensure that reefer meets all the FDA standards including Food Safety Modernization Act (FSMA).

Moving perishable goods without proper cooling systems could mean a loss of load and revenue and possible fines.

Refrigerated trailers can maintain temperatures between 65 to -20 degrees F.

In addition, some trailers consist of multiple temperature zones, allowing you to transport different kinds of cargo within the same trailer.

Reefer Trailer Temperature Ranges for Goods:

1. Produce

Produce is one of the most common freight transported on reefer trailers. Produce is what we consume. So, it’s likely that the temperate must stay consistent to ensure better food safety.

Product look is also a big factor when it comes to its purchase. Did you know 90% of purchasing decisions are made subconsciously? Many studies show that it takes customers seven seconds to decide whether to buy the product or not.

It means good packaging of your product makes an excellent first impression on consumers. Maintaining FSMA standards for reefers along with proper documentation and vehicle cleanliness is also crucial.

- 31˚F – 36˚F: Greens, stone fruits, apples, cruciferous vegetables, berries, grapes

- 38˚F – 45˚F: Cranberries, avocados

- 40˚F – 45˚F: Green beans, potatoes, sweet potatoes

- 45˚F – 55˚F: Watermelon, tomatoes, cucumbers, citrus, bananas

2. Poultry, Dairy, Meat, and Fish

One of the biggest problems with the transportation of meat is bacteria growth. They must remain at 40 degrees F or lower.

Typically, meat products are frozen during transport and then later on defrosted for display. It prevents deadly microbes from becoming active.

3. Pharmaceuticals

Pharmaceuticals are also perishable goods that proper temperature control to ensure chemical stability.

Elevated or sub-zero temperatures can cause issues like separation of emulsified products or sedimentation. They also need to be shipped timely to ensure effectiveness.

Remember, reefer temperatures for pharmaceuticals differ hugely depending on the chemical compounds. Ask your pharmaceutical manufacturer for ideal temperature before shipment.

Common temperature categories for pharmaceuticals include:

- Refrigerated: 2˚C -8˚C

- Room temperature: 20˚C – 25˚C

- Cryogenic: below 0˚C to as low as -150˚C

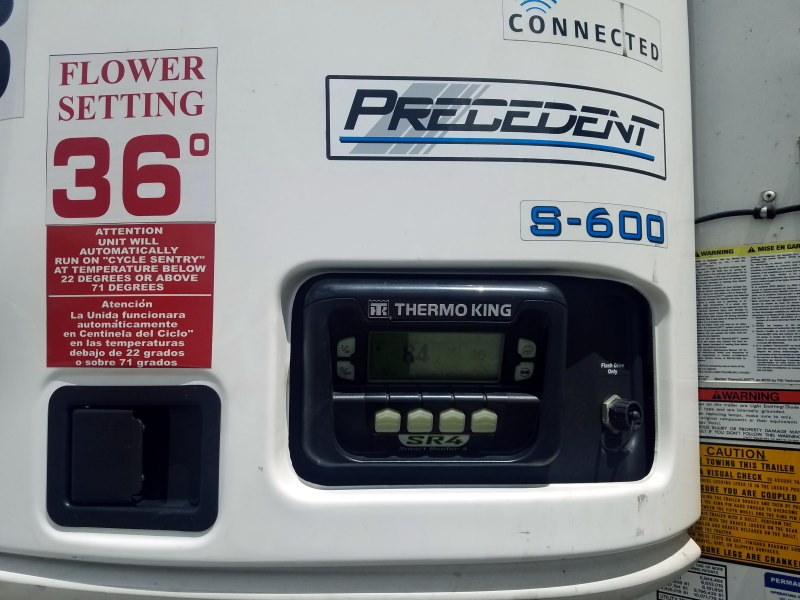

4. Florals and Plants

Same as other products, plants and florals need be stabilized and stay cool, as excessive heat ruins them.

The best reefer temperature for fresh-cut flowers and plants is at 36 degrees F. Another essential factor to take into account is the humidity level.

Flowers and plants begin to lose humidity quickly when they are picked or cut. But luckily, reefer trailers have in-built humidity controls that can be used to control moisture levels.

Reefer Containers

Reefer containers are refrigerated containers. These enclosed units are used in freight forwarding.

They look the same as regular containers but have an in-built freezing system that controls the temperature of the cargo. Each container has its own refrigerated unit.

How do Reefer Containers Stay Cool?

Cooling a reefer container is accomplished via two methods:

- Cryogenic Cooling – Melts frozen carbon dioxide ice to keep the items cool

- Diesel-powered generators – These generators attach to the container pulled

Why Are Reefer Containers White?

You might have noticed reefer containers pained in white. Well, white shade reflects sunlight instead of absorbing it. That is why they are white.

What is Reefer Trailer Temperature Monitoring?

Reefer Trailer Temperature monitoring means ensuring the proper temperature in refrigerated trailers, or reefers, and containers during transportation.

Regulating and maintaining the temperature is essential for shippers for various reasons, such as:

- Ensuring that customers get high-quality goods safely and on time

- Prevent unsafe temperature fluctuations for the shipment of perishable items per FSMA Regulations

- Save money by reducing the total number of rejected deliveries

Temperature Recorders for Reefer Trailers will record, or log what happens en route, at set intervals. This allows you to extract the data if any problem or dispute arises.

Some software systems allow you to monitor trailer usage and offer alerts on the temperature when it increases or falls below a specific programmable temperature threshold.

How does a Refrigerated Trailer Temperature Monitoring System help Trucking Companies and Cold Chain Suppliers?

With the increasing demand for speedy shipment and deliveries, product distributors are finding the best solution to please their customers.

They are not just looking to deliver items fast but also keeping an eye on freight damage, product loading, and temperatures.

Did you know there are more than 500,000 refrigerated trailers in the United States alone? Some costing upwards of $60,000.

Therefore, a refrigerated trailer temperature monitoring system offers an excellent solution for handling perishable goods and ensures a longer shelf life to boost profits.

Cold chain suppliers need to keep food and other perishable products at a consistent and safe temperature.

Federal rules allow shippers and drivers responsible for assuring the safety of products via the Food and Drug Administration (FDA) and the Food Safety Modernization Act (FSMA).

Due to the high degree of risk related to ingesting spoiled items, these rules are enforced strictly. Also, a perishable item transported for long-duration needs frequent monitoring and maintenance to ensure proper delivery.

Digitization of the supply chain not just boost tracking of reefer container itself, but also offers better management and control on the cargo.

Wireless refrigerated trailer tracking technology plays a vital role in maintaining the proper temperature in trailers during the transport of temperature-sensitive and perishable items.

This includes fresh products, personal care products, pharmaceuticals, seafood, vegetables, dairy, meat, fruits, plants, etc. The main goal is to prevent the contamination of perishable goods during transportation.

Remember, as the temperature increases; the product spoilage rate increases. Without a temperature monitoring system, food items such as meat, fish, veggies, etc. spoil fast.

As per the Healthcare Distribution Management Association, approximately 10% of medical items such as vaccines and blood products are sensitive to temperature change.

1. Improve Public Health and Safety

As per the CDC, near about 48 million people get ill, and 3,000 die every year in America due to food-borne disorders.

Varying and improper temperature affects bacterial growth in food and is the main cause of food-borne illnesses.

This is especially true for temperature-sensitive items such as meat, frozen products, etc; and cargo transportation is one of the primary methods of product transportation.

Cold Container temperature monitoring allows you to protect public health and safety by ensuring proper temperature levels.

2. Ensure Regulatory Compliance

When a receiver accepts the load, they are held responsible for its safety. If the carrier or shippers fail to maintain proper temperature throughout the transportation, a receiver can reject the items.

However, ultra-modern fleet technology like reefer sensors allows cold chain managers to complete their jobs with much ease and confidence. It also offers the digital record of temperature data during the journey.

This helps them adhere to cold chain transport codes like U.S. Food Safety Modernization Act (FSMA) and other food safety rules by proving the reliability and safety of products delivered.

It ultimately helps transportation and delivery agencies to prevent hefty fines and rejected deliveries.

3. Reduce Cargo Waste

Did you know about one-third of food produced gets wasted or lost every year across the globe? Maintaining proper reefer temperatures lower the amount of wasted cargo and rejected loads.

Earlier, reefer temperature tracking was performed manually by the drivers to ensure the safety and freshness of the items, but are prone to human error.

However, the advancement in-vehicle monitoring and tracking solutions in transportation and the cold chain have resulted in increased efficiencies.

Real-time remote monitoring, temperature alerts, and monitoring via wireless sensors remove the need for drivers to check temperature manually.

Lowering the number of stops, reducing wear and tear, and preventing wasteful engine idling pose an impact on the cost and fuel efficiency.

In fact, monitoring trucks and vehicles in real-time using plug-in temperature sensors allow carriers and shippers to reduce food waste.

4. Increased Business Productivity and Revenue

Trailers allow fleet managers to generate revenue. So, they make sure that they stay productive and in tip-top condition.

Not having this vital tool operating at its optimal efficiency means a significant impact on the agency’s bottom line.

Also, most of the perishable items have a limited shelf life besides temperature sensitivity. That is why the prevention of traffic delay regions and efficient routing are a high priority.

Reefer trailer temperature monitoring offers valuable reports that trucking companies and fleet managers can use to optimize reefer performance.

a) Boost driver performance

GPS tracking systems allow fleet managers to monitor different activities of the driver. Tracking driver performance may help you prevent:

- Unauthorized use

- Extended breaks

- Bad driving practices that increase fuel consumption

- Aggressive driving habits

- Route deviations

In fact, by incorporating a GPS Tracker and Temperature Monitoring Device into overall fleet management systems allow carriers to lower the number of denied loads.

This reduces loss claims and delayed deliveries leading to happy customers and higher revenue.

Permanent Temperature Sensors for Best Cold Chain Monitoring

Reefer sensors offer real-time updates on the temperature for the whole length of trip, status, history reports, and location.

These sensors can be installed in the air return duct giving independent temperature readings and not interfering with the current air controller system.

It is best to have a temperature monitoring system that is permanently installed in the trailer instead of using small battery-powered devices that may fail or get lost during the cold chain monitoring journey.

Sensors alert the driver/dispatch when the temperature in the reefer trailer goes above or below a specified temperature.

It allows fleet companies to maintain high-quality control over all the shipments and fleet. Plus, it also helps them adhere to all associated compliance.

They actively track and monitor the location and temperature of reefers, thereby lowering temperature-related spoilage. In fact, integrating sensors also allow speedy dispatches.

Another bonus is that it allows the transportation agencies to recover lost or stolen reefer trailers quickly.

Remote-sensing units regularly record and transmit data such as:

- Temperature and humidity

- Airflow in the trailer

- Refrigeration unit performance

- Other reefer status information such as low fuel level in the fuel tank of reefer

Fleet operations personnel can access all the data via smartphone, desktop, or tablet. Digital dashboards let them track and monitor trailers’ performance and act quickly when required.

Reefer Sensors for Cold Chain Monitoring Benefits:

- Recording of Temperature range over the entire cold chain transport

- Decrease food waste and rejected/spoiled loads

- Guard consumers from deadly food-borne diseases

- A Permanently installed system is more reliable and easier to maintain

Combining Reefer Trailer Tracking & GPS Temperature Monitoring

Ideally, for Trailer Tracking a Reefer Tracking System should include both GPS Tracking and Temperature Monitoring in one solution.

The combination makes for an easier install and provides for simpler data management and analysis later. These benefits apply to heavy equipment and other mobile assets.

It allows fleet managers to verify pickup/drops, check their exact locations, and much more. Here are additional advantages:

1. Provide More than Just Trailer Location Tracking

Fleet managers know there is more to managing than just finding the location of the reefer trailer.

They need to know:

a) Work Status

- Has the driver dropped off or picked up a load?

- How many stops does the trailer stop on a given day?

b) Operational Health

- Are there any maintenance problems that need to be addressed?

- How many hours has the reefer trailer been used in a given week, month, or year?

GPS Location tracking not only allows them to locate stolen trailers but even pinpoint the location of incorrectly parked trailers.

Allowing transportation companies to deter criminal activity and makes overall management smoother.

2. Digital Data Logging

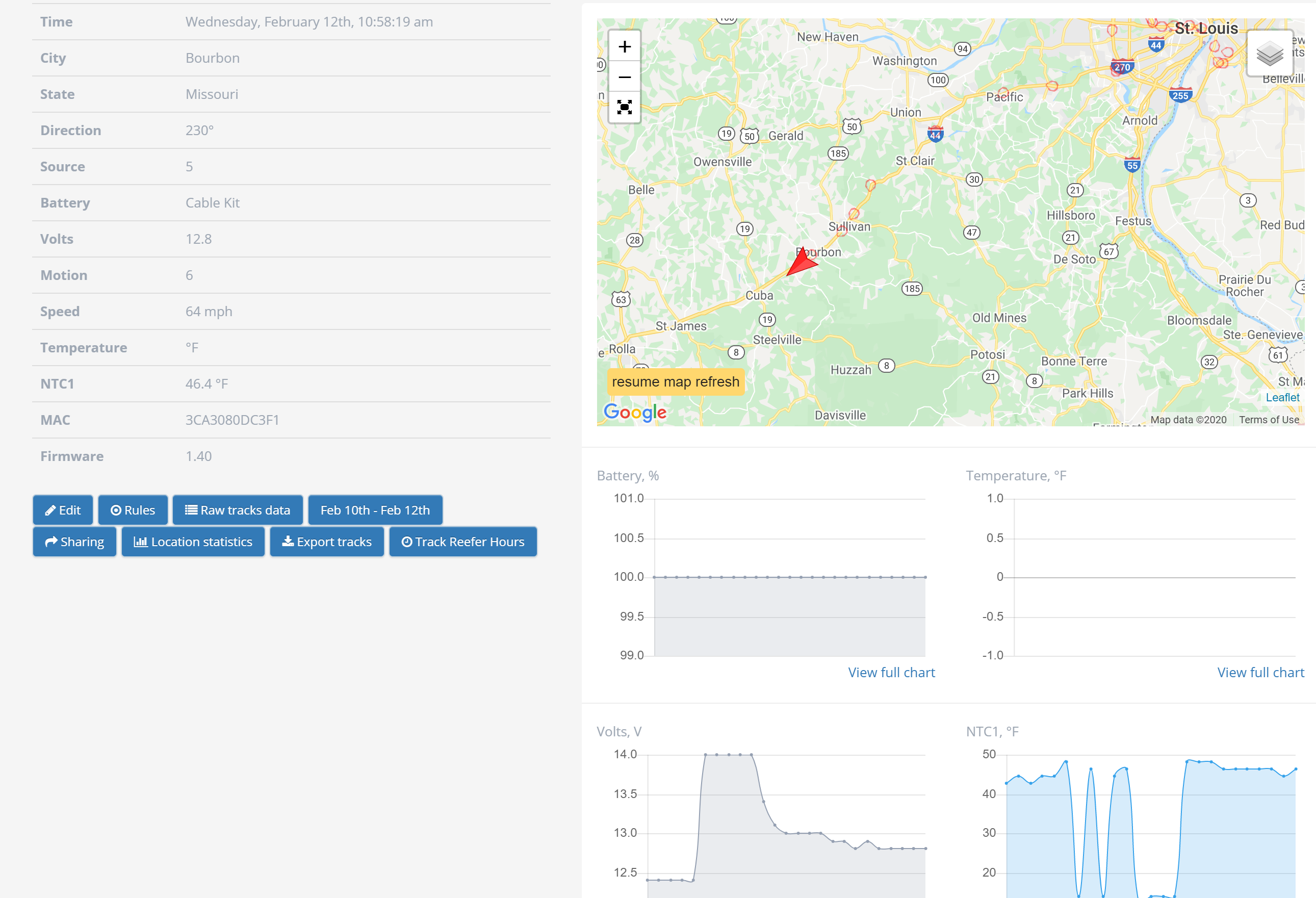

Digital Data Logging refers to the ability to record both GPS Location data and Reefer Temperatures at the same time, hence GPS Temperature Monitoring.

This is very convenient since it shows all data and times in a combined log, giving the carrier the ability to examine the log if the customer requests it, or claims a damaged load.

This digital log also ensures that the drivers do not make an unauthorized diversion with reefer trailers. It also serves as proof of your service monitoring.

Depending on the setting of the installed reefer tracking device, it will give you the location of the trailer.

Historical Logs can also be generated in Excel or csv format for printing or transmitting later.

3. Real-Time Temperature Alerts of Reefer Trailers

When trailer temperature monitoring systems are combined with GPS tracking technology, this allows the dispatcher to monitor refrigerated unit conditions remotely at all times in almost any location.

You can quickly view fleet in real-time using GPS tracking software and monitor temperature on the map for every trailer or vehicle, as well as get detailed reefer container temperature logs.

Furthermore, a GPS tracker linked to reefer can monitor up to 10 wireless temperature sensors at one time. It lets you monitor diverse areas of your refrigerated trailer well.

This can notify the manager instantly when the temperature deviates from a set range.

Trailer tracking devices typically send a location signal every 15 seconds to 47 hours, depending on your needs.

4. Better Customer Service

Both Temperature and Location tracking solutions allow transportation carriers to offer better customer service and accountability.

Temperature alerts and viewable temperature readings motivate fleet operators with information that assures successful and safe delivery.

5. Eliminate Wasted Time

The fleet managers need to ensure that the trailers are picked up from their location as soon as they get filled.

GPS reefer trailer tracking offers insights into everything. You can even set a geofence boundary around crucial locations like yard, customers. It provides alerts when vehicles enter and exit the boundary.

GPS trailer trackers pinpoint exactly where the trailer is located so that the driver does not sit idle in the yard for too long. This lower time wastage and ensures that everything goes well as planned.

6. Preventive Maintenance

Maintaining trailers is essential for fleet agencies. It is because it decreases the amount of downtime that fleet experiences while they are out for work.

Remember, the reefer unit breakdown is one of the main causes of cargo spoilage. It is also vital to keep water out of insulated cavities.

Trailers that have not been picked up by the driver for a long time may indicate mechanical problems.

By setting reminders and crafting a schedule allows companies to get automatic alerts when the maintenance date of the reefer date is due, approaching, or overdue.

This can enable them to replace a reefer trailer with another till your fleet is ready to hit the road again.

Also, GPS tracking devices provide timestamps at all ping intervals and allow you to answer questions like:

- Why is the driver not choosing a certain trailer?

- Why is the driver avoiding a section of the yard?

Remember, repairs made instantly to the interior and exteriors during damage keeps water out and boost its lifespan.

Furthermore, proper reefer maintenance helps you pass yearly inspections with much ease. It offers great peace of mind.

7. Lower Cost

Reefer remote control systems drastically reduce the cost and time of inspecting reefer containers. It allows the crew to react fast to the potential issues in the event of refrigeration unit failure.

Also, instant alerts allow fleet managers to fix the problem before it impacts the product.

Custom alerts can be set for:

- Power disconnection

- Temperature fluctuations that fall out of a specified range

- Unscheduled stops

- Reefer temperature controller status

- Deviations of routes

- Reefer container doors opened too long

Furthermore, efficient routing saves on labor, fuel cost while lowering excess wear and tear on the vehicle. In addition, tracking engine mileage and hours reduces engine maintenance and extends the warranty period.

8. Ensure High Product Quality and Compliance

Since Reefer Trailer Temperature Monitoring Systems can record all data while cargo is in transit, this can prevent and ensure the quality has been maintained throughout the cold chain cycle.

9. No Hassle

GPS tracker sends all the data in real-time. It offers you the potential to monitor, report, and get notified on data variances. The bonus point is that there is no hassle, and no special skills are required to get started.

10. Check Temperature at Any Point

Refrigerated temperature monitoring and GPS tracking combine location tracking and temperature monitoring in one device.

Some GPS Tracking Systems may also act as Data Loggers and Temperature Recorders which record the actual location measured by the temperature sensor, time, voltage, and other metrics.

Then, when the trailer returns to a home terminal, all the data is uploaded to be examined or shown to a customer.

Group mode allows you to track the entire fleet and reefer trailers on the same map at the same time. To check the live temperature of the trailers and vehicles, you just need to choose it on the map or mobile device.

11. Standalone Cold Chain Temperature Sensor

A combined GPS Temperature Monitoring System can even communicate with tiny, standalone cold chain temperature sensors to monitor cargo as it moves in and out of the trailer during transport and loading/unloading.

13. Door Monitoring

The use of a door sensor alert system allows drivers and administrators to get alert when the reefer trailer doors are open for a long time.

These alerts will show when the door was closed or opened at what time, by whom, and at what location.

14. Trailer Theft Prevention

Did you know most of the reefer trailers get lost without having a clue? Are they lost or stolen? No one knows. GPS tracking technology is beneficial for the fleets that require extra security.

A GPS Tracker that can also monitor and log the trailer cargo temperature is the ideal solution and allows trailers to be adequately secured while guarding cargo against thieves or spoilage.

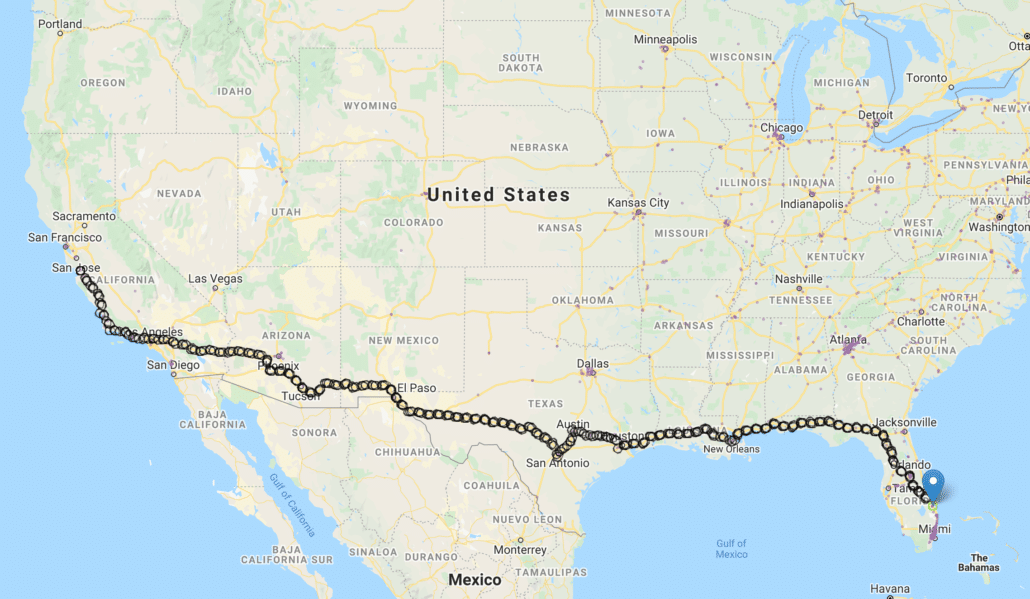

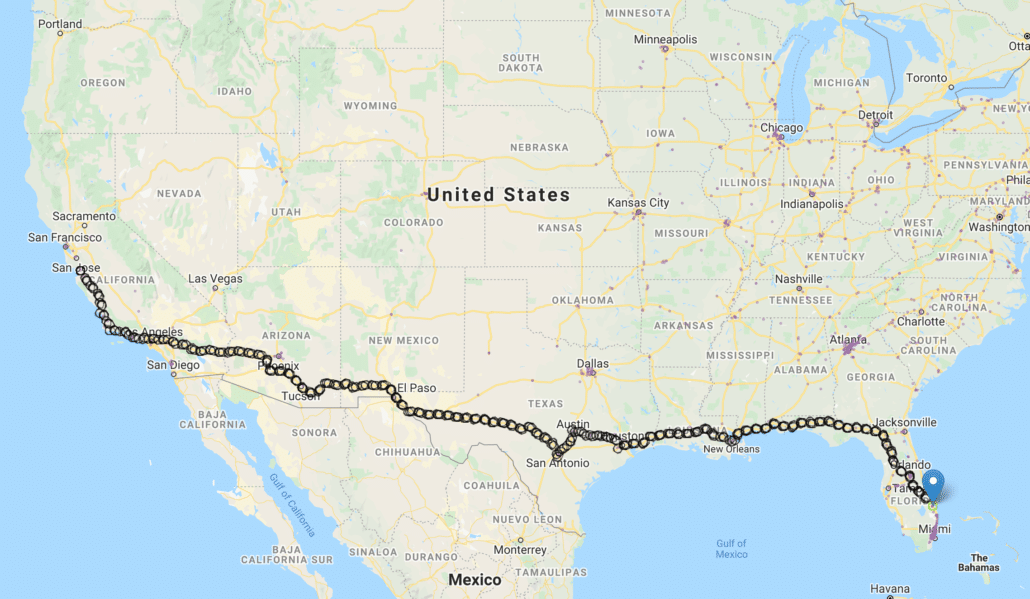

See Our Reefer Trailer Temperature Monitoring System with Integrated GPS Tracking:

It is paramount for the transportation, freight, and logistics agencies to keep perishable products at safe temperatures throughout the journey.

If you would like a Reefer Trailer Temperature Monitoring System, check out our system which has many of the features mentioned above.

Mention TOTAL20 for a 20% discount off of any order size.